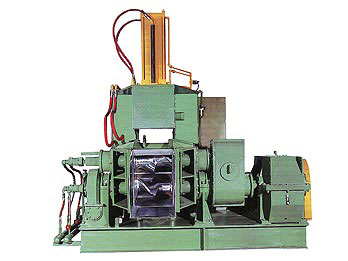

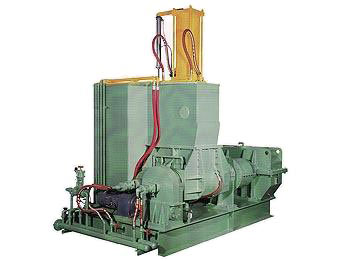

Enforce Compressible Dense Mixer

Enforce Compressible Dense Mixer

Product Model:Front Feed Type & Rear Feed Type

Front Feed Type & Rear Feed Type For Dispersion Kneader Machine

Speciality For Dispersion Kneader (Rear Feed Type)

- The mixer machine has an automatic temperature and time control system to provide a 100% mixing effect.

- Easy to clean chamber and changing colours.

- It mixes compounds in 6~10 minutes per batch eQur/alent to 2 units of mixing roller.

- Pressurized and sealing mixing chamber to provide high mixing performance and prevented environmetal pollution.

- Easy to installation operation and maintenance lower running cost.

Most Suitable Kneading Application For Dispersion Kneader (Front Feed Type)

- E.V.A. rubber & tpr, sole, rubber roller, hoses, belts, sponges, sportbolls, vibration insulator, elastic cord, sealing materials, tire, tapes, master batches, pigment, ink, automobile & electric rubber parts, chemical industry compounds.

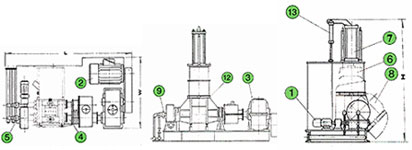

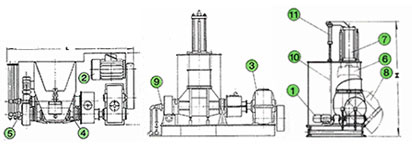

Diagram of Three Dimensions

|

|

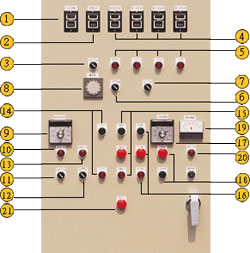

Power Distribution Diagram

|

|

Size

Mixing Axle